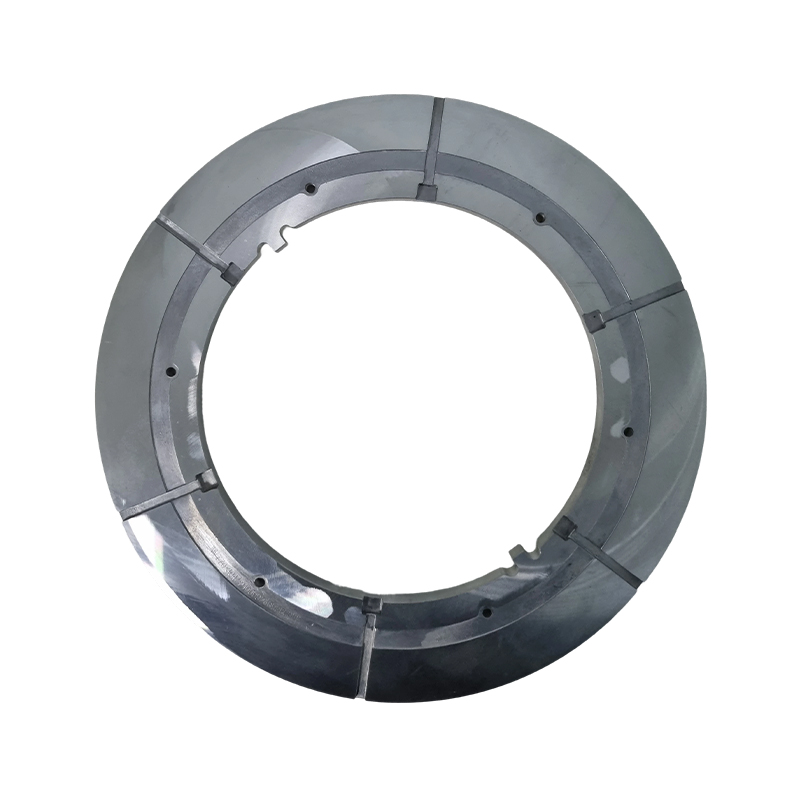

The compression of the sealing ring needs to be precisely controlled to avoid accelerated aging due to over-compression or leakage caused by insufficient compression.

- +86-18983383826

- lmianyazhu@163.com

- Fuluba Town, Xixiqiao Village, Huilongba Town, Shapingba District, Chongqing City